Omegon Mini Dobson Base

Introduction and Motivation | Introduction to Issues and Attempts to Resolve These | Look | Issues | Attempts to Resolve the Issues | Conclusions | Links

Archive

On this page, I present some information about my Omegon mini Dobsonian base with Synta dovetail (or prism rail) (purchased in July 2016). This is a simple table-top mount of Dobsonian type that is similar to the mount of the Sky-Watcher Heritage 100P Dobsonian telescope. However, it is white and a bit smaller (size-wise it seems to resemble the base of the Heritage 76).

| Note: I gave away the Omegon Mini Dobsonian base at the end of August 2018 and therefore cannot report any new information here. |

Introduction and Motivation

I had intended to use the Omegon mini Dobsonian base with the Sky-Watcher Heritage 100P and Sky-Watcher Skymax 102-OTA tubes, so that I would be able to use both tubes in parallel (the 100P has a base of its own, the 102 is just an OTA). I bought this base, among others, because of the following advertisement statements on the Astroshop Website:

- The advantages in a nutshell:

- wooden mini rocker box

- smooth movement in all directions via Teflon pads

- accommodates any telescope with Vixen / Sky-Watcher / Celestron mounting rail

- Smooth and easy moving rocker box

- The rocker box is made of wood and, like its big brothers, is mounted on Teflon pads. This means you can track objects very easily when observing - just push lightly on the telescope in the direction you wish it to move.

Note: Having stumbled across this advertisement once again, I sent an inquiry to Astroshop regarding the subjects of "Teflon pads" and "smooth movement", although I had "closed" this topic personally. I did so because, in my opinion, the black disks that I found between the base plates as a gliding support for horizontal movements were simply made of plastic and not at all Teflon. The subject of "smooth movement" is also addressed on this page: I found, however, out that, on my sample, exactly the discs were the cause why the movement was not at all smooth. Update (Oct 10, 2016): After my inquiry I received the following answer two days later:

|

Astroshop originally recommended this base for telescope tubes of up to 127 mm aperture (that is, for example, for the Skymax-127 OTA). According to my experience with the Skymax-102 on this base, I found this statement quite ambitious... In the meantime (October 2018), the mount is only recommended for Maksutov tubes of 80 to 90 mm aperture.

Unfortunately, this telescope base suffered, in the state that I bought it, from a number of issues, which I would also like to describe here, as well as the attempts of Omegon and myself, to address them.

First, I provide an introduction to the issues and to the attempts to resolve them. Then, I present photos of the look of the base alone and with the two telescope tubes. Thereafter, I illustrate the issues using photos, and finally the approaches of Omegon and me, to fix the issues.

Introduction to Issues and Attempts to Resolve These

Regrettably, it became soon clear to me that this base was not even worth its price of 30 EUR, because in practically every detail it was inferior to the Heritage 100P base. And, in my opinion, it also had, in the state that I bought it, two big issues.

- The prism rail (dovetail plate) slipped easily out of the holder, because, among other things, the locking knob was not chamfered at the end. So the holes in the prism rail were not met at the center, and the rail was tilted when I fastened the knob.

- The vertical axis had too much friction, so that the feet (or the base plate) slid whenever I wanted to rotate the telescope horizontally

I illustrate these and further issues in more detail and using photos further down.

Astroshop, which also stands behind the Omegon brand, had asked me soon after my purchase at their online shop for a rating of the product. Usually, I do not give any reviews, but this time I would have done so because I was so angry about the Omegon base. We went, however, on vacation first... Back from vacation, I sent an email to Astroshop with my opinion about the base and also communicated them the link to this page for further details. Astroshop then made two changes to the Omegon base, which were meant to eliminate the deficiencies that I had noted:

- The locking knob now had a chamfered tip to prevent that the prism bar accidentally slips out of the rail.

- The three plastic feet were supplemented by three small rubber feet, which are inserted into the existing feet. These feet are intended to prevent the base plate from slipping when the tube is moved in the horizontal direction.

Below, I describe in detail and using photos, how these changes affect my sample. In short, unfortunately the changes solve the issues of my sample only partially. I therefore took further measures to address these issues - and yet another one. I describe all this further down. Thus, the Omegon base was - within the scope of its possibilities - now "ready for use" for me. I cannot comment on to what extent the meanwhile improved Omegon bases are "ready for use". If the two swivel joints are still in the same condition as they were on my sample, I would still see room for improvement (for details, see below).

What was remaining? I think it was the cheap manufacture (whether that's an issue, is a personal thing, of course) and the lower stability compared with the basis of the Heritage 100P. The latter can also easily tilt over because of its three feet (over a "triangle side"), but not as easily as the Omegon base. In order to achieve the stability of the 100P base, the Omegon base would have to have a similar triangular base plate with feet at the corners (which would, of course, make it less transportable). Such a project would be a case for do-it-yourself...

With these improvements, I used the Omegon base especially for the lightweight Heritage 100P tube, particularly when the Skymax-102 was used on the Heritage 100P base (e.g., when traveling). To my taste, the Omegon base was too easily tipped over that I did rarely dare to mount the heavier Skymax-102 tube on it. A slight inadvertent push against the tube could already cause the base to tip over.

Look

Unpacking

|

Package |

Opened package |

|

|

View from inner side |

View from outer side |

Oblique view |

|

Comparison with 100P base |

Ditto, seen from the other side |

|

Skymax-102 and Heritage 100P Telescope Tubes on Omegon and Heritage 100P Base

The following photos demonstrate how the Heritage 100P and Skymax-102 tubes look on the respective Mini Dobsonian bases.

|

Heritage 100P on its own and Skymax-102 on Omegon base |

Ditto, seen from the other side |

Ditto, tubes directed higher up |

|

Bases exchanged |

Ditto, Omegon base turned around so that both bases are oriented in the same way |

Ditto, both bases seen from the other side |

|

Telescopes seen from the front |

Telescopes seen from the back |

|

On the photos, the locking knob for the tubes was oriented so that the knob hit one of the three holes in the prism rail. This lead to different orientations for both bases.

Telescope Tube on Omegon Mini Dobson Basis

As an alternative to the Heritage 100P base, I also use the tube on a simple Omegon Mini Dobson base.

|

Skymax-102 on Omegon Mini Dobson Base |

Ditto, front view |

Ditto other side |

|

Ditto, rear view |

|

|

The diagonal mirror hits the ground plate. You cannot rotate the tube completely - not a real problem... |

Ditto, detail |

Ditto, detail |

On the photos, the locking knob for the tube was oriented so that the knob hit one of the three holes in the prism rail.

Issues

In the following, I present some of the issues that I encountered with the Omegon Mini Dobsonian mount, and compare it with the Heritage 100P-base in these respects. The complete Heritage 100P telescope costs currently about 125 EUR (I bought it for about EUR 100). So I think that the base itself is likely to cost not much more than 30 EUR, which should be comparable to the Omegon basis.

|

The two Mini Dobsonian mounts:

Omegon left, Heritage 100P right |

Ditto |

At first glance, not many differences between the two mini Dobsonian bases seem to exist, but three differences come already to my mind for a start when I look at the photos. All in all, in comparison, everything looks smaller, less, and cheaper for the Omegon... For details see below!

Materials

|

Damaged base plate after a

brief contact with something hard... |

The coating material of Formica that the Omegon base uses makes a "cheap" impression on me. I damaged it already at the edge, when I was a bit careless and hit something hard. The coating material of the 100P-based seems to be of higher quality, and I did not damage it up to now.

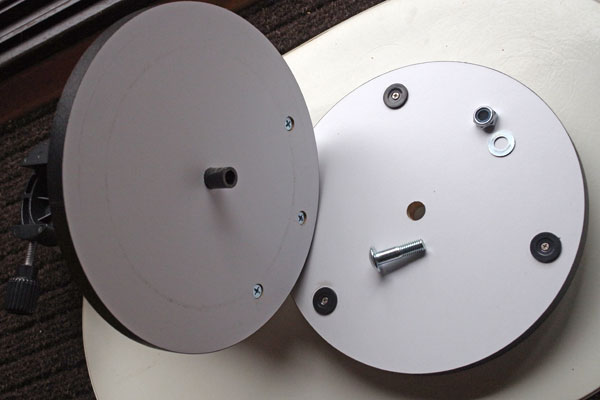

Stability

|

Base plate from above (Omegon

left, Heritage right with larger nut) |

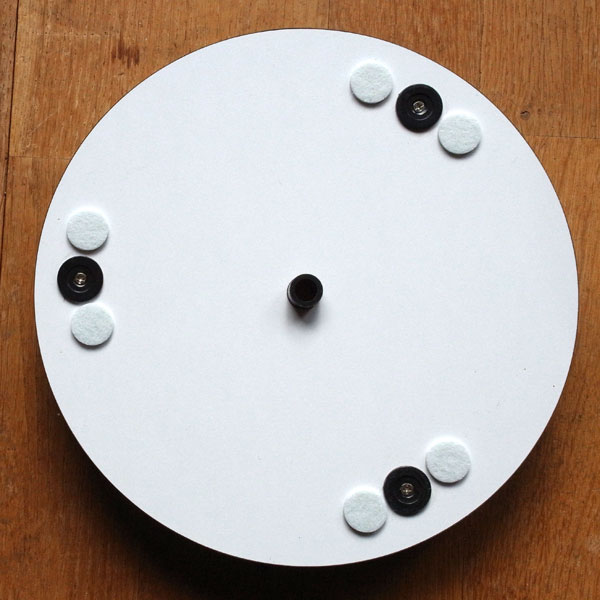

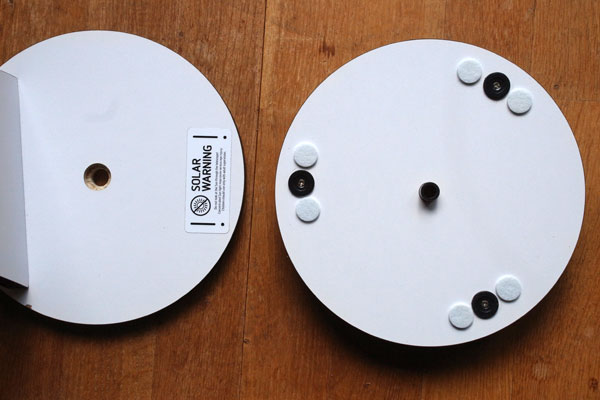

Base plate from the bottom (Omegon left, Heritage right with bearing???) |

See the difference in size of the feet (Omegon left, Heritage right) |

I do not expect super-stability from such a mini mount, but the triangular base plate and the larger feet of the Heritage 100P mount make it, of course, more stable. As a consequence, it needs a bit more space when traveling. The Omegon base is, however, considerably more "wobbly" than the Heritage 100P base. A slight push against the tube in the "right" direction was sufficient to get the base tipped over (at one of the "triangle sides"). The 100P base, too, is not necessarily safe against tipping over because of the three feet ...

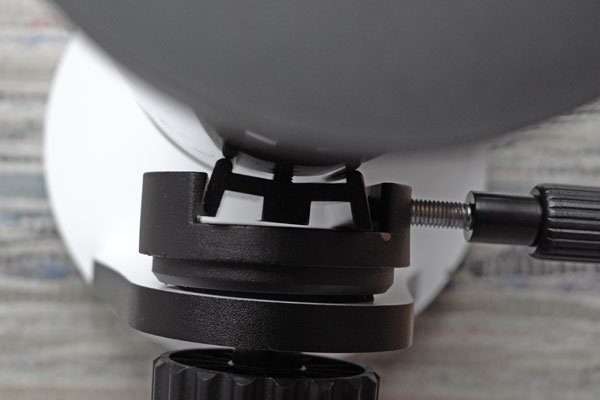

Vertical Axis

|

Base plate from above (Omegon

left, Heritage right with larger nut) |

Base plate from the bottom (Omegon left, Heritage right with bearing??? and tripod socket) |

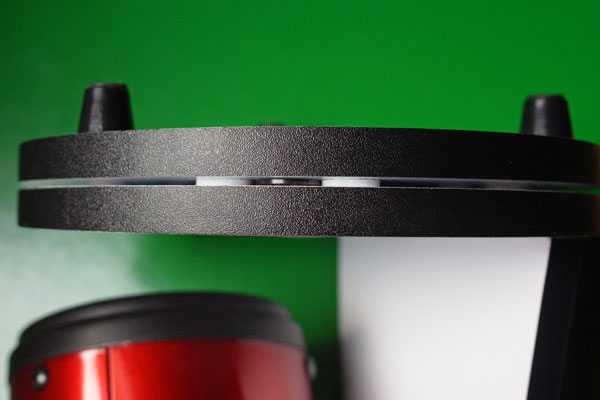

The Teflon pads (white) between the base plates are thicker for the Heritage base than for the Omegon base |

|

The Teflon pads (white) between the base plates are thicker for the Heritage base than for the Omegon base |

The black plastic pieces between the base plates are thinner for the Omegon base than for the Heritage base |

One side of the joint for the vertical axis (Heritage 100P base) - for comparison see the photo below |

|

Even the washer for the lock nut is smaller (the mother also) for the Omegon base... |

... than for the Heritage base (but it shows some rust...) |

The simple counterpart of the above photo for the Omegon base... |

The swivel joint for the vertical axis is more solid for the 100P mount in all aspects. As a result, the telescope can easily rotate around the vertical axis. With the Omegon base, the feet also slid across the table each time I turned either the lighter 100P or the heavier 102 tube (or even the base alone). It only helped to grab the base plate at the rubber feet to keep it from turning! Actually, a "no go" in my opinion...

The distance pads between the base plates of the Omegon base were made of plastic and are also thinner than the teflon pads used for the Heritage 100P base.

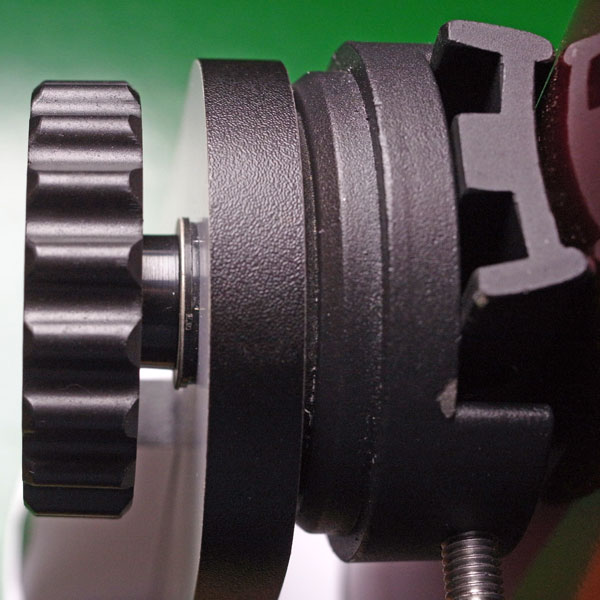

Thumbwheel for Fixing the Azimuth Angle

|

Thumbwheel (central locking

screw) for fixing the azimuth angle |

No washers at the thumbwheel for fixing the azimuth angle (Omegon base) |

Two washers (Teflon and metal) at the thumbwheel for fixing the azimuth angle (Heritage 100P base) |

The thumbwheel for fixing the azimuth angle (called central locking screw) was larger for the Omegon base, but provided much less grip than the one for the 100P base, which has deeper and thus firmer notches. The difference was noticeable especially when you had to loosen the fixed thumbwheel. And the 100P-base uses more washers, which makes the loosening and tightening smoother. The 100P base also uses washers (one made of Teflon and one of metal), which makes loosening and tightening of the thumbwheel easier. In addition, I found that, because of the washers, the tube can be tilted up and down more easily. With the Omegon base, you had to unscrew the thumbwheel for easier up and down movement of the tube a lot so that the tube slightly tilted to the side.

Prism Rail Holder, Locking Knob

Note: After my rating, the locking knob of the Omegon base was changed. For details, see below.

|

Prism rail holder |

Although the prism rail holders look virtually identical, the tube holds up better in the 100P version and does not slip out so easily. Another secret is hidden behind the locking knobs:

|

The locking knob has a "flat" end for the Omegon base |

The locking knob has a "round" end for the 100P base |

Comparison of the locking knobs (Omegon top, Heritage 100P bottom) |

And this happens with the Omegon base if you want to introduce the locking knob's end into one of the holes in the prism rail:

|

The locking knob does not meet the hole in the dovetail plate at the center ( Omegon base)... |

... and pushes the prism rail on the other side up - in the worst case out of the holder |

The locking knob of the Omegon base did not meet the hole in the dovetail plate (prism rail) at the center, pushing the prism rail on the other side up, in the worst case out of the holder. That happened to me once with the Heritage 100P, and it fell to the floor. Fortunately nothing was broken, but the shock was great. But, again and again, I found that the dovetail plate was not properly seated in the holder and was just about to slip out.

What can you do is such a case? Actually I wanted to use the holes in the dovetail plate to prevent tubes from slipping down in the case that I did not tighten the locking knob correctly. Obviously, I had to do without using the holes. I found that there were fewer problems when I used the side of the dovetail plate without holes. Then the end of the locking knob did not meet the rail "asymmetrically" and did not push the rail out of the holder. The tapered end of the locking knob of the Heritage 100P base reduced this problem, but unfortunately did not eliminate it completely. Somehow the holes in the prism rails did not seem to fit right... Now, when using other telescope bases, I also take care that everything fits well and that the prism rail cannot slip out of the holder. Actually I need three hands to fix everything properly ...

Note: After my rating, the locking knob of the Omegon base was changed. For details, see below.

Attempts to Resolve the Problems

After my assessment, Astroshop made two changes to the Omegon base, which were meant to eliminate the deficiencies that I had noted:

- The locking knob now had a chamfered tip to prevent that the prism bar accidentally slips out of the rail.

- The three plastic feet were supplemented by three small rubber feet, which are inserted into the existing feet. These feet were intended to prevent the base plate from slipping when moving the tube in the horizontal direction.

Astroshop sent me these parts in a small parcel. Owners of the original Omegon base should contact Astroshop to receive these spare parts as well. Here is the content of the package:

|

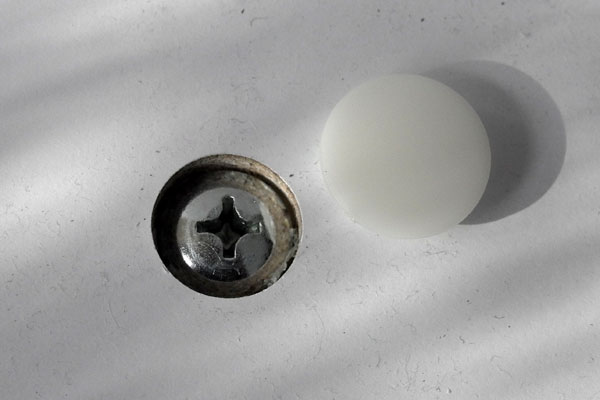

Package content |

Locking knob and rubber feet unpacked |

Ditto, larger view |

Locking Knob

The new locking screw was slightly smaller than the old one, but big enough. The tip of the screw was now slightly rounded (chamfered), although not quite as round as for the 100P base (it is more similar to the screw of the P130 base), but sufficient for a perfect function.

Here are the different locking screws in comparison:

|

P130, 100P, new, old |

P130, 100P, new, old |

P130, 100P, new, old |

Result: With the new locking screw I no longer have the problem that the prism rail tilts or slips out. Thus, Omegon has solved this issue !

Rubber Feet, Rotating Horizontally

The three small rubber feet were inserted into the existing feet. As a result, the feet on the table did not slip away so easily. Unfortunately, the rubber feet were quite loose and fell out of the feet again and again from the beginning. They were in danger of being lost quickly! Instead of sticking them to the feet, I put small screws from my radio amateur collection into the rubber feet and to make them thicker (the screw head was important for this...). With the screws inside, they now sticked much better to the feet. Admittedly, this was a somewhat special method...

|

Omegon Base: Foot without rubber foot (as delivered originally) |

Omegon Base: Foot with inserted

rubber foot (sent to me by Astroshop) |

Heritage 100P base for comparison:

Rubber foot inserted into "normal" foot to prevent gliding;

you can also see the Teflon piece that allows for gliding between

the two base plates |

|

Rubber foot with inserted screw to make it thicker for better fit to the foot |

Ditto |

Ditto |

The rubber feet should prevent slipping when moving the tube horizontally (the 100P base also has such feet, only larger - see right photo in the top row above). Now, the exciting question was: Can they do so? No, unfortunately they could not do it with my sample of the base (and my telescopes)! The friction on the horizontal axis was too strong and the stronger the heavier the telescope tube was (100P or 102 OTA). The rubber feet held the base better on the table than in the case that none had been there, but the friction of the joint was so strong that the base plate continued to slide on the table and rotated together with the rest of the base.

Result: The rubber feet improved the sliding behavior of the base, but could not prevent the slipping due to the high friction between the two base plates - that was only "curing symptoms" (like my holding the lower base plate by hand)...

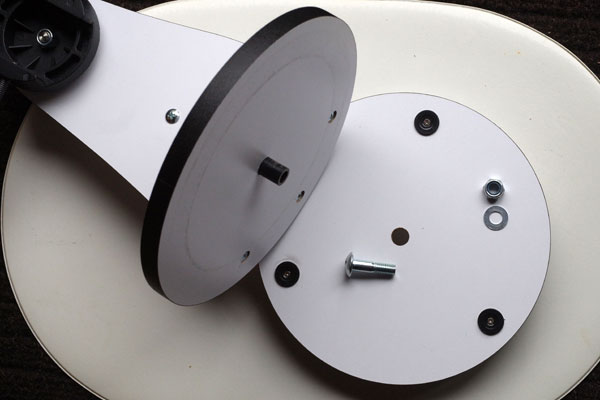

My Own Attempts to Solve the Issue...

What could I do - dispose of the base immediately or try to reduce the friction between the base plates? I decided for the latter and took apart the joint for the horizontal movement. And a first disappointment came into sight: Instead of Teflon discs, only simple plastic discs were used as spacers and gliding support. As I soon found out, they are the reason for the high degree of friction between the base plates.

At first, however, I found that part of the friction came from the black guiding sleeve for the screw that connects the two base plates. Actually, it should be fixed to the bottom plate and twist in the upper one. That worked out only partially, even though I noticed slight differences between both plates. The sleeve itself seemed to sit on one side more tightly than on the other (I noticed this when I turned the sleeve around). So I took out a round file and enlarged the central hole of the upper plate slightly. After assembling the plates again, the lower plate turned several rounds after bumping when I held it down. So the sleeve could no longer be an issue. However, if I turned the base upside down so that the weight of the base was put on the base plate, the base only turned about 1/3 turn after a similar bump. And on the table there was no improvement after this repair - the feet continued to slip when the base was turned - and this got worse with increasing weight / pressure.

A comparison with the Heritage 100P base showed that a similar bump also only led to a 1/3 to 1/2 turn in both positions. The joint also had a certain friction, but did not lead to any sliding of the feet and also did not increase unduly under load. So I concluded that the plastic disks between the base plates were the cause for the sliding of the feed when the base was turned horizontally.

But what material to take? Plastic seemed not to be a good solution to, so I tried out some felt rings (from potentiometer axes) that I found in my radio amateur collection. In fact, this seemed to work better than the original plastic disks. So I asked my wife to get out her handy collection of felt pads. And indeed, I found small felt pads, hardly thicker than the plastic discs, which worked well (plastic gliders did not seem to work so well). The pads should also be as thin as possible, otherwise the locking nut would not hold. For "safety reasons," I glued two felt pads next to each plastic disc. This is how my approach looks like:

|

Joint still taken apart,

base plate with felt pads and the original plastic disks |

Felt pads and the original

plastic disks viewed from the side |

Ditto, more oblique viewing

angle |

|

Joint still taken apart, base

plate with felt pads and the original plastic disks - smaller |

Joint put together again,

see the felt pads |

Ditto |

|

Another view of the felt pads |

Ditto |

Since the felt pads are slightly thicker than the plastic discs, the locking nut does not hold well on the screw any longer. Actually, I would now need a new screw, which is half a centimeter longer than the old one...

With these felt pads the friction is still there, but the feet no longer slip. The friction is also distributed fairly evenly over the 360 degrees. And it also works with both tubes! Thus, the friction does not increase too much with more weight on the joint.

Of course, I do not know how long this "repair" will work, but if the felt pads should be worn one day, I can get new ones from my wife...

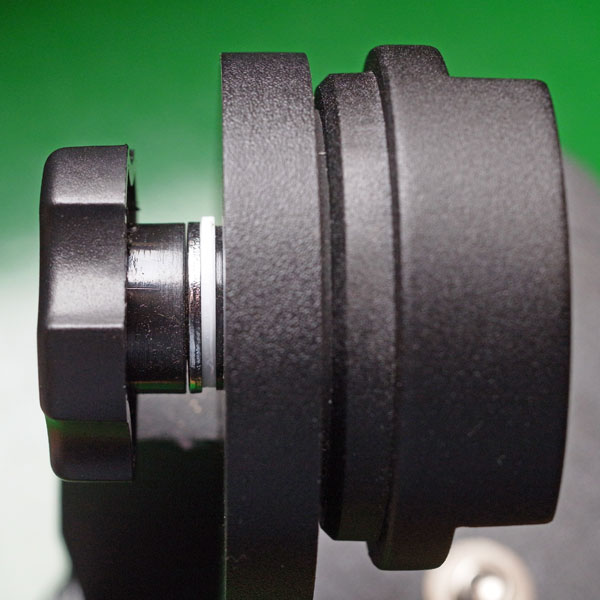

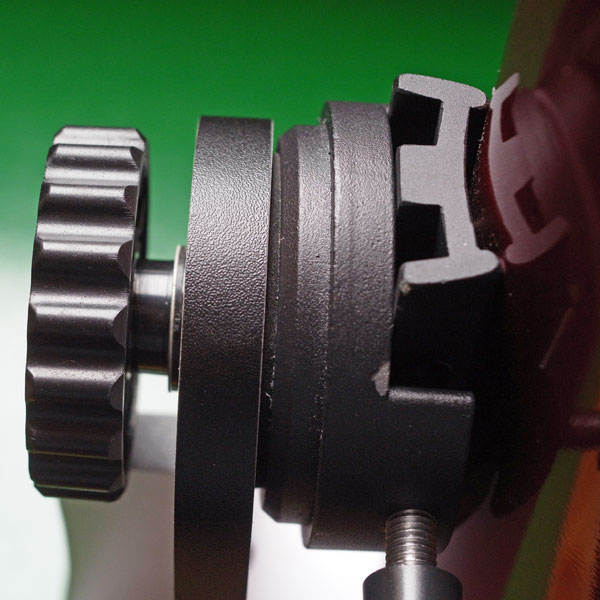

Pivoting the Tube up and down

Since I was already in "repair mode," I finally turned to the last remaining issue that the Omegon base had: the thumbwheel (central locking screw) or the second joint of the base. The thumbwheel had to be turned very far, whenever I wanted to pivot the tube up or down. At the 100P base, this went much easier, probably because of the included washers (see top right photo below), and I did not need to loosen the screw so far.

After I had unscrewed the thumbwheels of both bases, it turned out that they use different materials on the side, which generates the friction on the holding arm. Omegon used rubber-like material, Sky-Watcher uses material, which seems to me to be felt-like and is thus somewhat smoother and slips better. Originally, I wanted to mount rubber discs (from electric clocks) there at the Omegon base to reduce the wobbling, but this result made me change my mind. So I confined myself to installing on the side of the thumbwheel, similar to Sky-Watcher, a plastic and a metal washer that I found in my supplies. Unfortunately, I did not have any Teflon disks... Overall, this measure seemed to be useful, and the operation of the thumbwheel improved. I did not need to unscrew it as far as I had to, whenever I wanted to pivot the tube up or down.

|

100P joint taken apart; includes

two washers; the "friction" material looks like some sort of felt |

Omegon joint taken apart; no washers included; the "friction" material looks like some sort of rubber; after the disassembly, I had fine metal dust on my table... |

100P joint, with two washers

(metal left, Teflon right) |

|

Omegon joint; originally, there

are no washers |

Omegon joint, with two washers

added by me (metal left, plastic right) |

Ditto |

I mentioned the remaining issues already in the introduction.

Conclusions

The above examples demonstrate that the Omegon Mini Dobsonian base cannot keep up with the Heritage 100P base quality-wise. In addition, it exhibited two massive issues that Omegon addressed after my negative rating, regrettably only with partial success:

- The prism bar (dovetail plate) slipped easily out of the rail, because, among other things, the locking knob was not chamfered at the end. So the holes in the prism bar were not met at the center, and the bar was tilted when I fastened the knob.

- The vertical axis had too much friction, so that the feet (or the base plate) slide whenever I wanted to rotate the telescope horizontally.

Omegon was able to solve the first problem with a modified locking knob that was chamfered at one end. The second problem was addressed with rubber feet. This improved things a little, but, at least for my sample, did not solve the problem. Rubber feet are actually just an attempt to "cure symptoms." The real issue were, in my opinion, the plastic disks, which served as sliding aids between the base plates and caused too much friction. As long as Omegon does offer a solution for this issue, I hardly believe that I can recommend the base to others.

Finally, the joint for the azimuth angle also requires improvements or, at least, the introduction of washers, which would facilitate the up and down pivoting of the tube.

With the help of Omegon and with self help, I put the Omegon Dobsonian mini base in a workable condition, but actually this would have been Omegon's task from the beginning. The additional parts for the required improvements should cost only cents...

Addendum

In October 2018 I got a hint that the Omegon Mini Dobson Mount is now also available in a refinded version, the Omegon Mini Dobson Mount II. It is advertised as follows:

- The Mini Dobson Mount II is now even better than its predecessor - with rubber feet for a better grip on smooth surfaces and real Teflon pads for smoother movements.

Furthermore it now has a tripod thread, similar to the base of the Heritage 100P, allowing you to attach the mount to a photo tripod.

I take the reference to "real Teflon pads" as an admission that the predecessor model does not have Teflon pads, although it is still advertised as having those (quote: smooth-running in all directions, on Teflon pads)...

Links

- Pages from German

distributors for the Omegon Mount Dobsonian mini base with synta dovetail:

- Astroshop: www.astroshop.de/azimutal-ohne-goto/omegon-mini-dobson-montierung/p,46439 (in German) - www.astroshop.eu/alt-azimuth-without-goto/omegon-mount-dobsonian-mini-base-with-synta-dovetail/p,46439 (in English)

- Omegon (belongs to Astroshop): www.omegon.eu/de/azimutal-ohne-goto/omegon-mini-dobson-montierung/p,46439 (in German) - www.omegon.eu/alt-azimuth-without-goto/omegon-mount-dobsonian-mini-base-with-synta-dovetail/p,46439 (in English)

- Omegon Mini II Dobsonian mount: www.astroshop.de/azimutal-ohne-goto/omegon-mini-dobson-montierung-ii/p,53648 (in German) - www.astroshop.eu/alt-azimuth-without-goto/omegon-mini-ii-dobsonian-mount/p,53648 (in English)

- See also my page offering Astronomy Links.

| 26.10.2018 |